| Share/Comment | |||

|

Tweet |  |

|

|

Feedback |  |

|

Recall the quote in the "first step" section of this site, "You can manage, what you can measure; you can measure, what you can define; you can define, what you can understand". Operational definition is the first step towards effective management. It helps us build a clear understanding of a concept or a phenomenon so that it can be unambiguously measured.

Let us take a very simple example to understand the need and the concept of operational definition. Let us imagine a situation that we wish to buy an all-purpose shirt with 50% cotton and 50% polyester. Would you accept a shirt whose front is made up of 100% cotton cloth and the back made of 100% polyester cloth? Surely not! Clearly we need to (operationally) define what we need.

A better expression would be that we need a shirt made up of a cloth having even distribution of cotton and polyester fibers and their proportion by weight (or may be by number) is equal. So far so good, but we also need to have a mechanism to test it. In this case, we can send the shirt to a lab where randomly selected two areas (say 1 cm x 1 cm) - one from the back and one from the front are examined for the contents.

The lab reports that group of two fibers of each - polyester and cotton are interwoven to make this clothe. Did we mean alternate fibers of polyester and cotton or something else? We now discover that we even need to define "even distribution".

In a business management scenario, common words such as good, reliable, and accurate (etc.) can have multiple meanings unless they are (operationally) defined in a specific context.

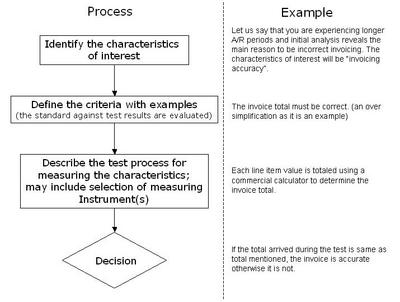

So how do we construct an operational definition? The process is explained with the help of an example in the following figure:

Document the outcome of each process step and that becomes the operational definition. The operation definition must be tested before it is rolled out.

comments powered by Disqus

Commenting Guidelines

We hope the conversations that take place on “discover6sigma.org” will be constructive in context of the topic. To ensure the quality of the discussion stays in check, our moderators will review all the comments and may edit them for clarity and relevance.

The comments that are posted using fowl language, promotional phrases and are not relevant in the said context, may be deleted as per moderators discretion.

By posting a comment here, you agree to give “discover6sigma.org” the rights to use the contents of your comments anywhere.